Smart Automation System > Smart Manufacturing

Tire Auto Production Equipment

-

Sorting/Stacking/Storing

1.Store 300,000+ pieces. 2. Shipping: 90 PL/hr out,45 PL/hr for return. 3. Packing: 10PL/hr out,10 PL/hr for return. -

Stacking/Transfer/Conveying

Loading, conveying, and unloading are all carried out continuously, and don't need to maintain a high transportation speed. -

Overhead Hoist Transfer(OHT)

Thinness, flexible gripper, 180 degrees rotation, 5G wireless transmission, conveying distance and track path can be designed according to cleanroom space.

Oil Auto Filling Equipment

-

50 Gallon Filling Equipment

Including opening station, buffer station, blowing station, filling station, alignment station and cap locking station, etc. -

1 Ton Filling Equipment

Used for filling various liquids, not affected by the thickness of the container, with high filling accuracy and fast filling speed.

Rubber Factory Auto Production Equipment

-

Rubber Factory Auto Production Equipment

Material supply machine, metering & feeding, lifter and checking the weight. -

Wrapping Machine

Goods can be transported safely, and large and heavy objects can be wrapped quickly and efficiently.

Electronics Factory Auto Production Equipment

-

Converter Auto Produciton Equipment

Real-time upload of production information, built-in precision sensors, effective early warning of insertion abnormalities. -

Water Glue Bonding Line

High lamination precision, high elasticity and quick mold change, can correspond to lamination of diverse products.

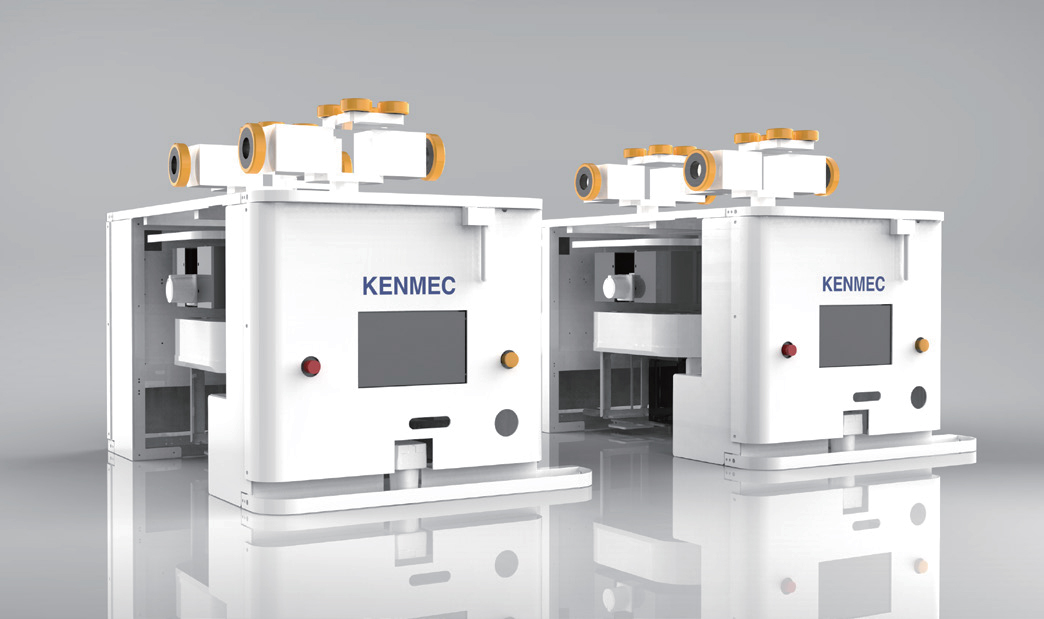

Coffee Bean Auto Production Equipment

-

Coffee Bean Auto Production Equipment

Bag opening machine, air conveying piping, stone picking, color sorter, baking machine, cooling, and packaging. -

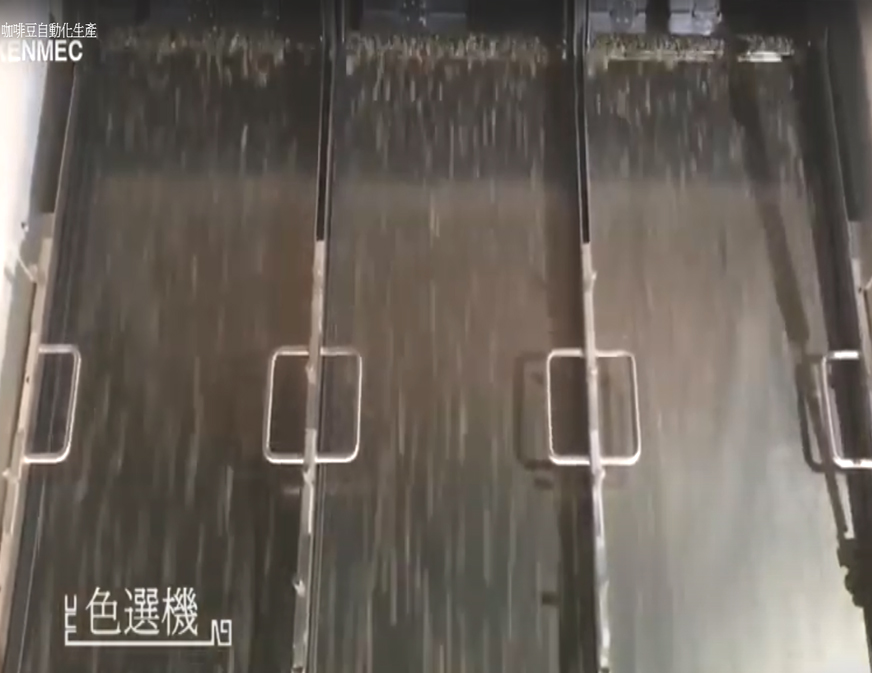

Color Sorter

Automatically distinguish the color of coffee beans and sort them by lane.

Wine Factory Auto Production Equipment

-

Wine Bottle Guiding

Guide the whole team of wine bottles and proceed to the next stage of grabbing and stacking boxes. -

Wine Bottle Grabbing/Boxing/Stacking

Ensure a higher packing speed, the bottle grabbing head must be able to grab the bottle in a short time without falling.

Sugar Factory Auto Production Equipment

-

Sugar Factory Auto Production Equipment

Raw sugar unloading, conveying to silo, moving trolley, unloading and stacking, conveying to refinery, filling/sewing, stacking to storage. -

Whole Sugar Factory Auto Production

From equipment to construction, it is designed and planned by KENMEC. We provided one-stop service to customer in this case.

Solar Cell Auto Production Equipment

-

Wafer Loading Unloading System

The auto wafer loading and unloading system can load wafer quickly and it is safe and stable. -

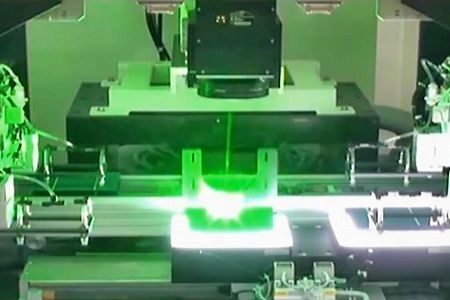

Cell Laser Insulator

Laser marking is carried out along the edge of the wafer to isolate the positive and negative p/n contacts, fully automatic, high productivity, and high precision. 。 -

Solar Cell Production Lline

Innovative technology, high efficient automation, intelligence monitoring are the main characteristics of the solar cell production line. -

Silicon Wafer Loading/Unloading System

Loading /unloading system for chemical vapor deposition (PEVCD) process.

Thin Film Solar Module Auto Production Equipment

-

Thin Film Solar Module Production Line

Reduce amount of raw materials under same light-receiving area, and thickness can be 90%+ lower than silicon solar cells. -

Thin Film Solar Module Cleaning Machine

Through the process of brushing water section, high-pressure washing section and air knife section to clean solar module.

Traditional Factory Auto Production Equipment

-

PVC Pipe Auto Handling Stacking System

The AGV goes under the material truck and pulls it to the designated position and separated from the material truck. -

Lifter AGV

1. Match with the production line for flexible dispatch and dispatch. 2. Effective use of space. 3. Judges the battery power, AGV automatically goes to the location for charging.

TFT Factory Auto Production Equipment

-

G6 Stocker & Overhead Conveyor

Transports the panel more robustly and send it to the stocker for storage at a stable speed. -

G6 Color Filter Conveyor System

Transports the panel to the required place at a more stable speed. -

G7.5 Color Filter Conveyor System

Transports the panel to the required place at a more stable speed. -

G8 Panel Packing and Unpacking System

Use robot to put substrate in the box, close upper cover and discharge.Then take out substrate and return empty box back. -

G8.5 Glass Handling Equipment

Integrates various equipment to provide a full solution for conveying system including straight, trnsfer, rotation, and temporary storage. -

Auto Peeling Machine

Take the glass out of the pallet, use the this machine to tear the film, and then discharge the pallet.

Website MapCopyright © 2018 KENMEC MECHANICAL ENGINEERING CO.,LTD. All rights reserved.