Home » Applications » Petrochemical / Traditional Industry

Petrochemical / Traditional Industry

Petrochemical / Traditional Industry

-

Chemical ASRS

1. Save labor. 2. Operation is quick and accurate. 3. Improve the management level of the warehouse. -

Rubber Factory Auto Production Equipment

Material supply machine, metering & feeding, lifter and checking the weight. -

Coil Gantry System

Gantry applications reduce transportation costs and increase productivity and safety. -

PVC Pipe Auto Handling Stacking System

The AGV goes under the material truck and pulls it to the designated position and separated from the material truck. -

Lifter AGV

1. Match with the production line for flexible dispatch and dispatch. 2. Effective use of space. 3. Judges the battery power, AGV automatically goes to the location for charging. -

Non Pallet Stacking of Fertilizer Bags

Auto filled and sealed, sent to upper floor by climbing conveyor, compacted, and cross-stacked. -

Salt Packet Pallet Auto Stacking

Tthe stacking step is started after the direction is changed by the steering machine. The stack is first pressed and then stacked. -

Wrapping Machine

Goods can be transported safely, and large and heavy objects can be wrapped quickly and efficiently. -

50 Gallon Filling Equipment

Including opening station, buffer station, blowing station, filling station, alignment station and cap locking station, etc. -

1 Ton Filling Equipment

Used for filling various liquids, not affected by the thickness of the container, with high filling accuracy and fast filling speed. -

Sorting/Stacking/Storing

1.Store 300,000+ pieces. 2. Shipping: 90 PL/hr out,45 PL/hr for return. 3. Packing: 10PL/hr out,10 PL/hr for return. -

Stacking/Transfer/Conveying

Loading, conveying, and unloading are all carried out continuously, and don't need to maintain a high transportation speed. -

Indoor Circulation Cultivation System

Collecting data through auto equipment and wireless networking technology greatly saves manpower and precision breeding. -

Non-Toxic Biotechnology Cultivation System

Practice one-stop system integration from hatching, nursery, growing fish to harvest. -

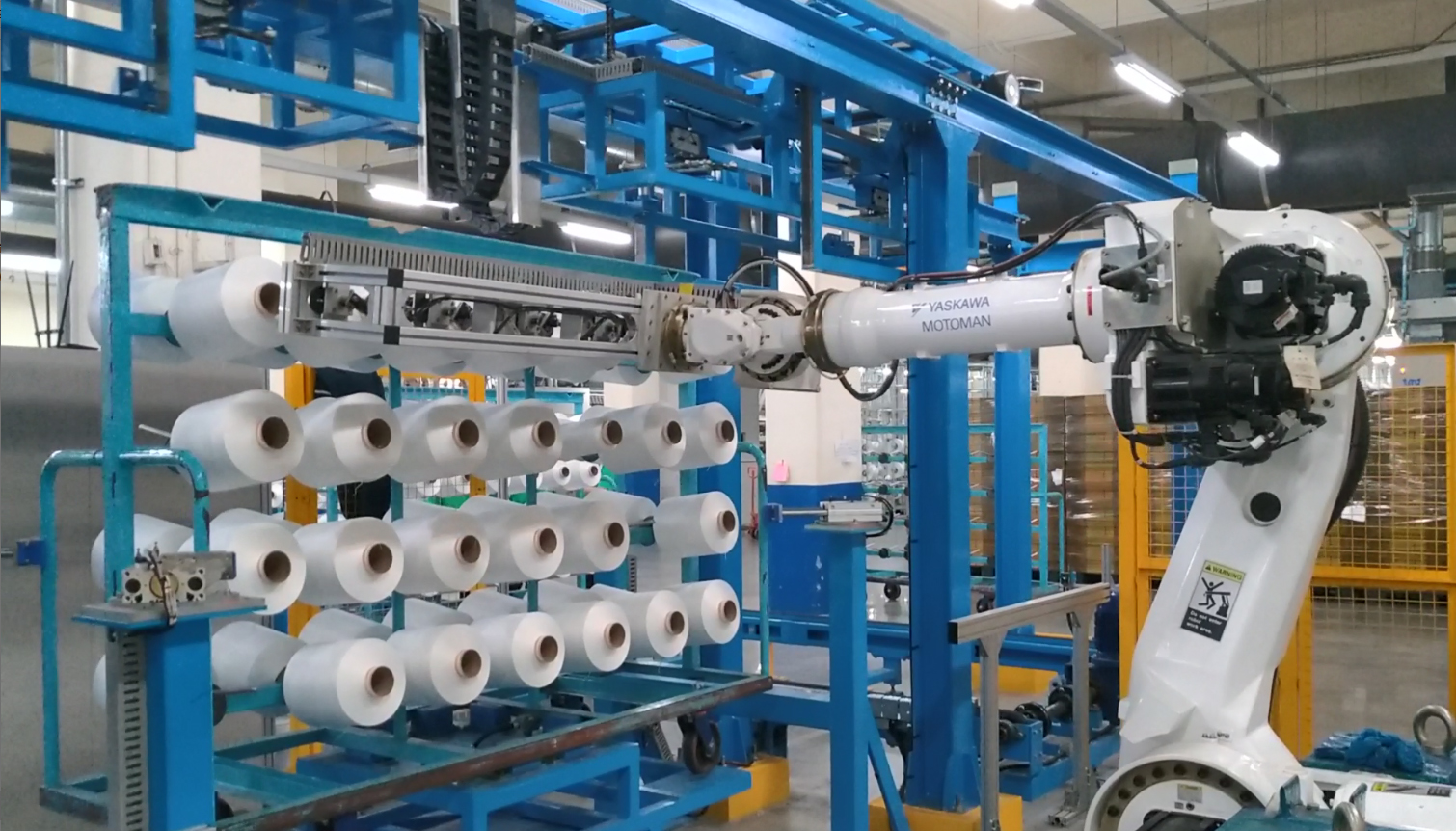

Twisting Yarn Winding and Picking

Continuous elevator, labor-saving device, robotic arm, carton sealer, and various belt conveyors. -

Plastic Bag Stacking

U-shaped screw feeder, automatic weighing machine, automatic packaging, pp bag folding and sealing machine, high-bed stacking machine.

Website MapCopyright © 2018 KENMEC MECHANICAL ENGINEERING CO.,LTD. All rights reserved.