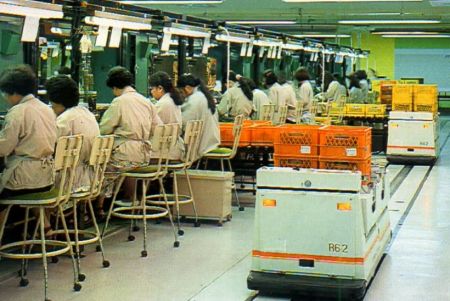

Home » Applications » Electrical and Electronic Industry

Electrical and Electronic Industry

Electrical and Electronic Industry

-

Converter Auto Produciton Equipment

Real-time upload of production information, built-in precision sensors, effective early warning of insertion abnormalities. -

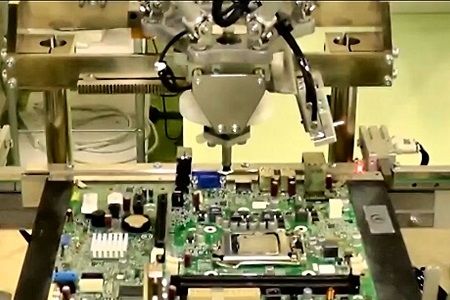

Robot Application in Electronics Industry

It can be used for automatic positioning and plug-in of electronic parts of different sizes and shapes. It is accurate and fast. -

Auto Stacking for Electrical Appliances

Adjustable stacking equipment can greatly reduce the damage rate of electrical goods caused by artificial stacking and transportation. 。 -

Water Glue Bonding Line

High lamination precision, high elasticity and quick mold change, can correspond to lamination of diverse products. -

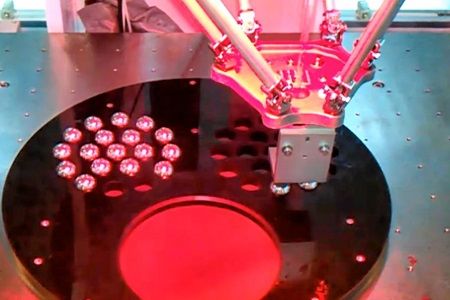

Steel Ball Positioning

Precise positioning, grab the steel ball at the specified location and place it on the specified location, accurately and quickly. -

Bicycle Parts ASRS

Fully utilizing space, managing goods entry and exit with a WMS system, ensuring quick and accurate processing and inventory management. -

Mechanical Parts ASRS

Pallet type ASRS, goods weight 1300kg, RGV for picking supply. -

Electronic Components ASRS

Automatic warehouse with 4,786 slots for plastic boxes, 782 pallet positions, and integration of WCS with the existing ERP system.

Website MapCopyright © 2018 KENMEC MECHANICAL ENGINEERING CO.,LTD. All rights reserved.